1

The gut core is mounted onto the hooks at each end of the string machine.

2

The gut core is stretched with a cloth so the gut fibers are pulled out to full length. This helps to stabalize the coe for the windings.

3

The carrage behind the string core carries a spool of fine thread that is wound on to the length of the core . It is difficult to see because the thread is so fine.

4

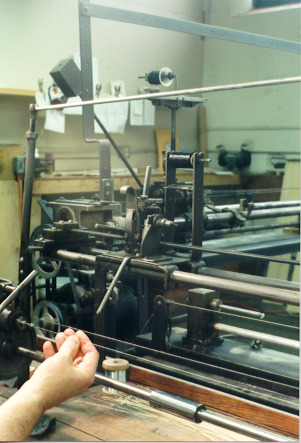

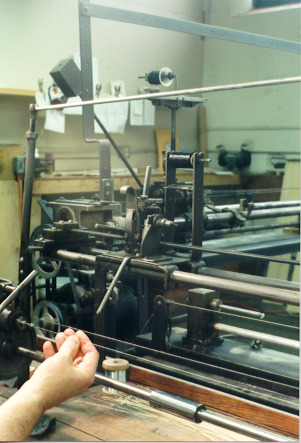

The carrage crawls along the tracks by means of a threaded rod. The underlay is wound around the core at regular intervals not quite touching together.

5

The wire is wound onto the core over the thread underlay. Two fine wires are applied with one pass.

6

The left hand guides the wire over the core length and the rigtht hand sqweezes the wires onto the core tightly while adding a bit more stretch.

7

The wire wire is round when it is wound onto the core. It must be polished down so the surface of the string is smooth. Sandpaper is used to smooth the string as it rotates between the spindles.

8

Afert polishing, the thread stocking is wound onto the end of the string.

9

The stocking binds the wire at the end and keeps it from unwinding.

10

The stocking is sealed with a little glue to keep it on place.

11

Another stocking is started to the other end of the string.

12

A longer stocking is wound onto the other end of the string to bind the wire and protect the part of the string that winds around the peg.

13

A drop of glue to seal the thread finishes the string.